Colin Baird

World War II had just ended. Japan lay in ruins. In three large cities, millions of people had just witnessed the destruction of sixty five percent of their nation’s infrastructure. Food rationing brought even the nation’s elite to the streets of Tokyo, just to seek out their daily ration of 800 measly calories and whatever else could be found lying in the streets. Manufacturing of any type, like fingernails dragged along a chalkboard, ground to a screeching halt.

Yet, in spite all of this, and in spite of the potential for future hatred that one country might harbor towards another after such utter devastation, Japanese leaders like Emperor Hiro Hito elected to remain true to their nation’s culture, and true to their great heritage. The Japanese people whose humility, curiosity, and creativity drove their intrinsic need to learn and to improve, would soon discover how to make these already admirable human traits, even more important staples in the now highly desirable Japanese diet of future economic prosperity and self reliance.

Victorious Americans-war now behind them, seemed satisfied from their leader’s war time efforts. Leadership had after all, at least temporarily, instilled within the American people a meaningful purpose, a distinct aim if you will. The American employee’s creativity and curiosity-much like their Japanese counterpart’s, were fully engaged and at very high levels.

For America it was a happy time. Leaders had proven they could accomplish great things by investing on their employees. Employees had in turn, proven to their leaders they would invest in their leadership given the proper motivation and incentives. Flags were raised with pride as people celebrated and danced on Wall Street. Fathers, mothers, and children wept, consumed by the raw emotion as their families reunited.

Then, the Americans went back to work. It was time to return some degree of normalcy to their lives. But this time, engagement would seem different. What was the cause they were working towards? What purpose had they now; especially since the war had already been won? Would life now mean just another drab and dreary day in the plant or in the office? For America, a country whose employee’s minds, skills, and mutual cooperation had just lifted her out of one crisis, another crisis was about to begin. The nation that had once been the hunter, was about to become the hunted.

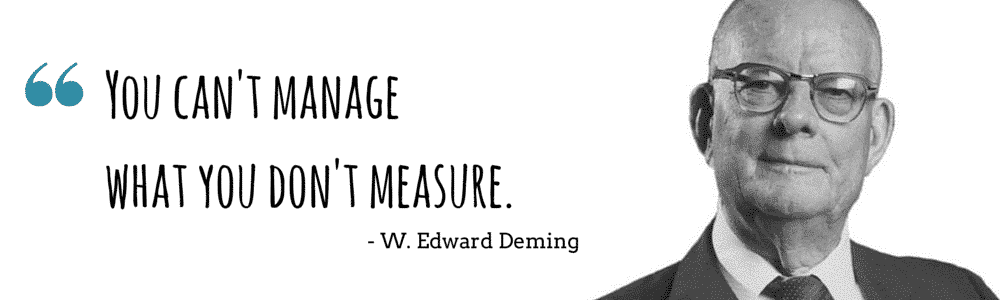

Ironically, the passion of one man – a man who had just led the Americans out of one crisis, was about to lead the Japanese out of another. And after Dr. W. Edwards Deming’s teachings had been fully embraced and then woven deftly into the culture of Japan, Toyota slowly began to rise out of the ashes.

Their curiosity engaged, their creativity enabled, the Japanese people moved forward towards their goals of greater economic prosperity and self reliance – self reliance they had so desperately sought long before the second world war even began. Deming and the Toyota family, then began developing a bond that would last from the early 1950’s until Deming’s passing in 1993.

And one day, almost out of nowhere, but well beyond their immediate post war production crisis; just as Deming had promised the Toyoda family, their company-Toyota became the world’s best people company; one where respect became its culture’s guiding principle and leader’s true north.

Oh yeah, I forgot one minor detail. They would become the world’s best car manufacturer too.

But Toyota doesn’t just build and improve profitable cars. Toyota builds and improves profitable leaders. Profitable leaders who in turn improve profitable people. And Toyota’s answer to the life-long question of “Are leaders born, or are they developed?” well, it’s an emphatic and resounding yes. That’s because Toyota invests in leaders who invest in people . And they invest in a manner that shows respect for the person, while many other leaders remain oblivious to its intrinsic benefits.

So what makes Toyota such a unique company? One whose leaders are effective, efficient, and clearly think and reason differently than others?

1. While leaders within other cultures look for creative ways to drive employees out of their jobs due to normally occurring variation-effectively turning people into causes, Toyota leaders look to find ways to drive the normal variation out of the system by increasingly challenging the employees to do so – therefore turning the causes behind variation into opportunities for improvement. They do so by engaging employees in discovering the ugliness behind variation’s actual root causes.

2. I mean variation’s deepest, ugliest root causes. The ones that drive productivity down; the ones you have to work really hard to find-especially sitting in an office just reading or completing reports. You know, the variation that creates the kind of a problem that keeps curious and creative people up at night because of their eagerness and excitement to find an answer to a problem, along with learning more cool new stuff first thing in the morning and then throughout the day? And did I say all people are curious and creative and want to learn cool new stuff all the time? Because if I didn’t, I should have. That’s the kind of motivation I’m talking about creating. It’s motivation you simply can’t buy. Let’s just refer to curiosity and human creativity as the People’s Intrinsic Motivators, PIM for short.

3. And yes, I said an answer, not the answer, and I also said a problem, not the problem. That’s because every problem is a new opportunity at Toyota to engage People’s Intrinsic Motivators in finding an answer. Now that’s a problem, because it’s not the answer some leaders are looking for, but it’s a problem with numerous benefits in spite of this. Problems require solutions, and solutions require fully engaged people using their own curiosity and creativity to figure out what the problem is, where it’s coming from, why it’s occurring, and finally, testing out new theories and ideas to improve the conditions that caused the problem to manifest. Everyone at Toyota is taught a specific method to solve a problem. And whether you are an executive or a mechanic, an engineer or an accountant, solving problems is your badge of honor within Toyota.

4. And speaking of problems and variation, they are the opportunity within the Toyota culture that never stops giving. They give employees an opportunity to share with one another their individual talents, and they give leaders opportunities to develop new skills and methods that flow from each team member’s talents and ideas. Ideas that are tested by employees, proven viable by employees, and then shared with others by fellow employees. These ideas are then share up and down the entire supply chain. Talk about collaboration; someone please kick me, this simply can’t be true. I wonder, do politicians who create public policy on so called “monopolies,” even understand basic systems thinking?

5. As Deming taught Toyota-along with anyone else in Japan who would listen, (sadly, American leaders wouldn’t, that was until it was too late) costs are not causes; rather costs come from causes. Variation therefore provides the holy grail of opportunities that presents itself in the form of a problem. This enables Toyota leaders to engage man’s curiosity and creativity in problem solving, which in turn, helps everyone become more productive. This activity creates increasingly greater people skills that are then used to eliminate further activities viewed as wasteful to the customer, disrespectful towards the employee, and unprofitable for the organization. While that is just touching on three bases, that’s still what I call a home

Throughout the years, Deming taught Toyota the four areas contained within his system – a system which he would later copyright the name to, that is: The System of Profound Knowledge (SoPK). It consists of Appreciation For A System, Knowledge Of Variation, Theory Of Knowledge, and Theory of Psychology – all parts which met the unique needs of Toyota at just the right time in history. (1)

So voila, problem solved right? All I have to do is mimic Toyota, find the cause(s) behind my company’s variation, and my business is fixed? No, because if you believe you can simply “fix” your business like you tie your shoes in the morning, by substituting someone else’s specific knowledge with yours about how and why their system functions the way it does, you are missing the point. It’s the “why” behind why your business system exists not someone else’s that drives your culture. It’s showing the respect for “your” people that should help you drive the “why ” behind for what purpose your business exists.

Many people don’t see the need to integrate Appreciation of A System, Knowledge of Variation, Theory of Knowledge and Theory of Psychology all together. They instead pick parts from this approach, missing valuable opportunities to dive deeply into what is possible when man is completely engaged. But they all must go together for the system to function how it is intended to perform.

Toyota has proven time and time again, people are the most fundamental element of any system, and improving them is a leaders unique responsibility. A responsibility everyone even remotely affiliated with the company, both inside and outside of it, feels a deep sense of purpose to make possible for the millions of lives we can and choose to touch each and every day.